About

Collecting accurate and detailed data about your electromagnetic field and radio frequency exposure is one of our specialties.

We provide comprehensive EMI/RFI environmental testing to minimize impact on electronic equipment, telemetry & diagnostic systems, communication systems, computers & CRT monitors, servers and IT networks, scientific research instruments, etc. It is important to perform an assessment if the following pertain to your facility:

- Nanoscale/high-resolution in character

- Diagnostic and research medical imaging/ testing facilities

- In proximity to strong DC magnets

- In proximity to high-power broadcast or communications transmitter

- Installation sites for multiple RF transmitters (rooftops)

- Utilizing RF Spectrum

- Classified, Sensitive, Secure

- Utilize Radio Frequency Identification systems (RFID)

- Highly automated with sophisticated control systems

Testing

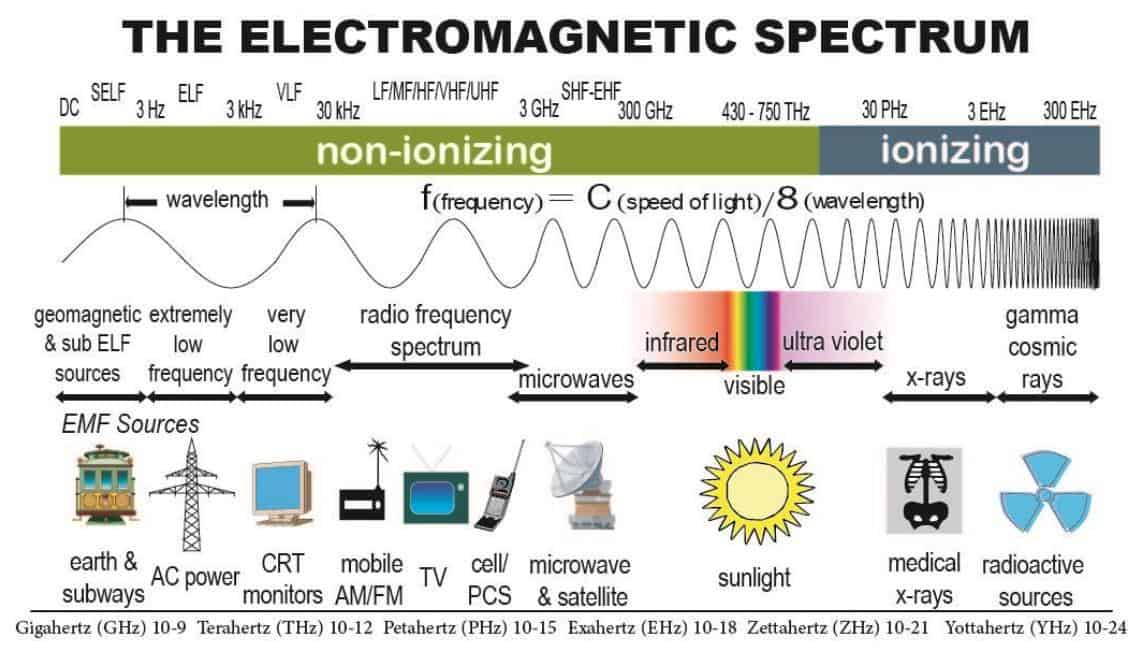

Full-Spectrum Testing from DC to 26 GHz

Our engineers and trained technicians maintain a high standard of quality assurance during the performance of EMI/RFI environmental testing recording EMI and RFI data in Research, Hospital, Industrial and Commercial Facilities. To read more about what your specific needs are, click on one of the services below.

Services Provided

EMI/RFI Testing

Full-spectrum DC, AC ELF, and RF Environmental Testing

Full-spectrum DC (0 Hz) to 26 GHz professional electric and magnetic field (EMF) environmental testing services of new construction sites and existing buildings, will reveal the impact of electromagnetic (EMI) and radiofrequency (RF) interference on equipment, imaging systems, and ensure conformity to various IEC/EN, FCC, and human exposure standards. We test non-ionizing frequencies up to 26 GHz:

- Geomagnetic/Static DC electric/magnetic frequency sources from (0 Hz – 10 Hz)

- Sources Include: geomagnetic, electrified or diesel trains, vehicles, MRIs, NMRs, research/ramping magnets and processing equipment

- AC ELF (extremely low frequency) electric/magnetic frequency sources from (3 Hz – 3000 Hz)

- Sources Include: transmission/distribution lines, transformers, switchgears, busways, risers, conduits, panels, subways/trains, electronics, etc.

- VLF (very low frequency) and LF (low frequency) frequency sources from 3 kHz – 30 kHz

- Sources Include: electrotechnical equipment, high resolution display systems, florescent lighting systems, etc.

- RF (radio frequency) electric/magnetic frequency sources from 14 kHz – 26 GHz

- Source Include: mobile, marine, UHF/VHF, cell/PCS, radar, radio navigation services, government time radio stations, military communication, etc.

- PQ (power quality) electrical sources (harmonics, voltage/current surges, etc.)

EMC Testing

Electric and magnetic field site surveys of a device, building or site (future or existing) are selected by EMF emission sources and required bandwidth:

- Industrial Scientific & Medical (ISM) RF frequencies E and H field (i.e., heat sealer) compliance site survey (13 MHz, 27 MHz, 40 MHz, 915 MHz, 2.45 GHz, 5.8 GHz and 24 GHz)

- FCC Part 15: Class A & B, Unintentional and Intentional Emission Compliance (30 MHz – 1 GHz) both Radiated & Conducted Emissions (0.5 MHz – 30 MHz)

- 644-1994 IEEE Standard Procedures for Measurement of Power Frequency Electric and Magnetic Fields from AC Power Line

International EMC standards (limited version):

- IEC 61000-6-1:2016, Electromagnetic Compatibility (EMC)- Part 6-1: Generic standards for residential, commercial and light-industrial environments

- IEC EN 55035:2017 Immunity Standards for Multimedia equipment for computers, IT, broadcast receivers, audio & studio equipment

- IEC 55032:2012 Radiated Emission Standards for Multimedia equipment for computers, IT, broadcast receivers, audio & studio equipment

- MPR II Swedish Compliance for VLF/LF CRT computer monitor (5 Hz – 400 kHz)

Military compliance standards & requirements:

- MIL-STDs-449, -461, -462, -464, -1472, & -2169

- MIL-HDBKs-235, -237, -240 & -454 & MIL-EP-1110-3-2

- NSTISSAM TEMPEST/1-92, NSTISSAM TEMPEST/1-95

- IEEE-STD-299 (replaced MIL-STD-285 for shielding performance testing)

HEMP/EMP performance in compliance with the standards:

- MIL-STD-188-124, MIL-STD-188-125

- MIL-HDBK-419, MIL-HDBK-423

- NSA 65-5, NSA 65-6, NSA 73-2A & NSA 94-106

Product Emission Testing

Do you need product emission testing on various electromechanical and lighting systems? We can provide in-house testing of fan filter units and motors, variable frequency drives (VFDs), LEDs, fluorescent, and incandescent lighting systems.

Ground /Net Ground Currents

Electrical infrastructure will degrade in older buildings or due to N.E.C violations (i.e., grounded neutrals, wiring errors, etc.). Ask us how we can evaluate the building grounding plans and identify potential ground loops that can generate elevated and high magnetic fields emissions in new buildings.

- IEEE, N.E.C. & N.E.S.C electrical standards and Power Quality (PQ) criteria

Stray Voltage

See Stray Voltage Investigation.

FCC Compliance & RF Testing

We measure and record electric field strength (V/m) and magnetic field strength (A/m) from various RF sources from 14 kHz – 26 GHz. Including electric field, plane wave, and microwave sources:

- RF Sources Include Intentional & Unintentional (spurious): mobile, marine, UHF/VHF, cell/PCS, radar, radio navigation services, government time radio stations, military communication, distributed antenna systems (DAS), etc.

- Typical sources include: TV/AM/FM Broadcast transmitters, WiFi Nodes & Cellular Phones

- Typical sources include: Variable Frequency Drive (VFD) pumps and motors, fluorescent light ballasts, RFID scanners and/or heat sealers

Radio Frequency Interference (RFI), is increasingly an issue for siting sensitive instruments, communications system design and operation, and human RF exposure safety.

RF interference assessment is a requirement for:

- Sensitive medical devices (e.g. MRI’s, NMR’s, EEG’s, MEG’s)

- Sensitive research equipment (e.g. STMs, some AFM’s, certain cryogenic

- amplifiers, CCD’s, and other applications)

- Commercial Grade recording/production studios

- Systems employing RFID (e.g. manufacturing, medical)

- High-Rise buildings with first-responder/cellular repeaters

- Safety Systems – Elevator Controllers, Environmental controls

- Dense RF transmitter environments (rooftops, etc.)

Evaluation EMF human exposure/risk assessment standards for government and military personnel, contractors, and visitors based upon: ACGHI, NCRP, IRPA/INIRC, OSHA, WHO, DOD, and the FCC OET Bulletin 65 Evaluating Compliance with FCC Guidelines for Human Exposure to Radiofrequency Electromagnetic Fields.

See standards below:

- RF – electric/magnetic field site survey (14 KHz – 26 GHz)

- Industrial Scientific & Medical (ISM) RF frequencies E and H field (i.e., heat sealer) compliance site survey (13 MHz, 27 MHz, 40 MHz, 915 MHz, 2.45 GHz, 5.8 GHz and 24 GHz)

- FCC OET Bulletin 65 Addition 97-01, Evaluation Compliance with FCC for RF Human Exposure Limits, (300 kHz – 100 GHz)

Rebar & Continuity Testing

Epoxy coated rebar testing is performed to evaluate and assess the continuity (resistance) in ohms between adjacent epoxy coated steel rebar members and uncoated rebar sections. This service is highly recommended for NMR, MRI and electron imaging facilities during pre-construction to ensure minimal ground/net current magnetic fields directly beneath EMI sensitive research tools.

Bus Testing

For shield performance and verification testing, we use a high current and high magnetic field (1 mG up to 4,000 mG RMS) 3 phase copper bus test to expose the shielding to the predicted or simulated magnetic field environment.

Human Health Standards

When People Are at Risk

People are typically exposed to very high 50/60-Hz magnetic field levels ranging between 10-1,000 mG (milligauss) when their offices and apartments are next to, over or under transformer vaults, network protectors, secondary feeders, switchgears, distribution busways and/or electrical rooms. Usually employees and tenants are not aware of this potential hazard unless the magnetic field source compromises audio/video equipment, electronic instruments, magnetic storage media, VDT’s, computers, and networks. Once detected it ultimately becomes the responsibility of the building owner/manager to remedy, otherwise the employee and/or tenant may seek legal action. Unfortunately, there are only three practical solutions to mitigate magnetic field exposure produced from electrical systems within buildings: move the victims (people and equipment) away from the source, shield the source or shield the victims from the source.

EMF human exposure/risk assessment standards for government and military personnel, contractors, and visitors based upon: ACGHI, NCRP, IRPA/ICNRP, OSHA, WHO, DOD, and the FCC OET Bulletin 65 Evaluating Compliance with FCC Guidelines for Human Exposure to Radiofrequency Electromagnetic Fields.

- International Commission of Non-Ionizing Radiation Projection (ICNRP), limits of exposure to static magnetic fields: 2009, (0 Hz)

- ICNRP:2010, For Limiting Exposure to Time-Varying Electric and Magnetic Fields (1 Hz – 100 kHz)

- ICNRP:2009, Guidelines for Limiting Exposure to Time-Varying Electric, Magnetic and Electromagnetic Fields (up to 300 GHz)

- C-95.1-2005 IEEE Standard for Safety Levels with Respect to Human Exposure to Radio Frequency Electromagnetic Fields, (3 kHz – 300 GHz)

- C-95.6-2007 IEEE Standard for Safety Levels with Respect to Human Exposure to Electromagnetic Fields, (0 Hz – 3 kHz)

- FCC OET Bulletin 65 Addition 97-01, Evaluation Compliance with FCC for RF Human Exposure Limits, (300 kHz – 100 GHz)

Noise & Vibration

Vibration and Acoustic Testing- A New Service Offered By Vitatech.

Vitatech is pleased to introduce vibration and acoustic measurements to our industry leading EMI/RFI surveys. These new capabilities allow us to provide comprehensive site analysis, both pre and post development, for the Semiconductor, Nanotech and CryoEM markets. Vitatech is using the best industry standard equipment and processes to produce vibration and acoustic reports that can stand alone or be utilized by other consultants.

Most equipment that is sensitive to magnetic fields is also sensitive to noise and vibration. Multi-sensitive equipment examples are E-beam, CD-SEM, STEM and FIB tools in the semiconductor industry; MRI, Cryo-TEM in the medical field and most especially research tools like NMR, SEM, EPMA, and Aberration Corrected STEM/TEM. These tools universally have complex site requirements that demand precise and detailed planning.

Combining surveys for EMI, acoustics and vibration can streamline development, especially at the site selection and preparation phases of a project. Timely, comprehensive and accurate information allows more definitive selection of strategies. The result is better decisions made with a high degree of confidence.

Case Studies

Altavista Power Station

Vitatech was hired by the Altavista Power Station to visit their site premises to...

Read MoreUniversity of Southern California

University of Southern California (USC) expanded their research initiatives to construct a new 170,000...

Read MoreNC A&T and UNCG Collaborative Building

Vitatech was commissioned by HDR Architecture in November of 2008 to perform an initial...

Read MoreOrange & Rockland

In January of 2009, Vitatech analyzed the impact of the overhead single-circuit vertically arrayed...

Read MoreUniversity of Ottawa

A feasibility study was performed at the University of Ottawa MacDonald Hall site in...

Read MoreUniversity of New South Wales

The Sydney light rail expansion is planned to service the University of New South...

Read MoreUniversity of Sydney

The University of Sydney hired Vitatech as the owners representative to ensure AIN has...

Read More