About

Our Guaranteed Magnetic and Radio Frequency Shielding Systems.

What is Passive Magnetic Shielding?

Rigid (passive) magnetic shielding is divided into two fundamental types based upon the magnetic and conductive properties of the shielding materials: flux-entrapment shields and lossy shields:

A flux-entrapment or flux ducting shield is constructed with a permeable (μ) ferromagnetic material such as low-carbon steel, silicon-iron steel (oriented and non-oriented) and nickel-iron alloy which either surrounds (cylinder or rectangular box) or separates (“U” shaped or flat-plate) the victim (i.e., people or equipment) from the magnetic field source. Ideally, magnetic flux lines incident upon the flux entrapment shield prefer to enter the permeable (μ) material via the path of least magnetic reluctance ℜ, rather than pass into the protected (shielded) space. The higher the permeability the more magnetic flux lines will prefer to travel within the material rather than a lower permeable material including air (or vacuum) which has the lowest mu (μ) of 1.

Lossy shielding depends on the eddy-current losses that occur within highly conductive copper and aluminum materials, and higher permeable (μ) ferromagnetic materials that are also less conductive. When a highly conductive materials are subjected to a time-varying (60Hz) magnetic fields, currents are induced within the material that flow in closed circular paths, perpendicular to the inducing field. According to Lenz’s Law, these eddy-currents oppose changes in the inducing field, therefore the magnetic fields produced by the circulating eddy-currents attempt to cancel the larger external fields near the conductive surface, thereby generating a very effective shielding effect.

What’s Your Shielding Factor?

Shielding Factor (SF) is the ratio between the unperturbed magnetic field Bo and the shielded magnetic field Bi as expressed in: SF = Bi/Bo The final shielding design depends on several critical factors: maximum predicted worst-case 60-Hz magnetic field intensity (magnitude and polarization) and the geomagnetic (DC static) field at that location- whichever is greater; shield geometry and volumetric area; type of materials, permeability, induction & saturation; and, number of shield layers.

To Shield or Not to Shield?

It is usually not desirable, especially if office or living space is limited, to evacuate an entire room or several rooms exposed to very high magnetic field levels. So, when space is at a premium the only other alternative is magnetic field shielding. To shield or not to shield the source? That is the question! Generally, when physically practical, source shielding is the most effective and least expensive alternative. However, if there are multiple magnetic field sources (i.e., parallel transformer vaults, network protectors, secondary feeders, etc.) it may not be economically feasible to separately shield each source. In that case shielding the room, and consequently the victims, is the preferred solution.

Shielding

Guaranteed and Cost Effective Mitigation Solutions.

Vitatech specializes in research, scientific and medical diagnostic shielded enclosures. For more than 25 years, Vitatech has shielded high magnetic field sources such as substations, network protectors, switchgears, electrical rooms, risers, busways, cable trays and more.

Upon client approval of our magnetic field management recommendation and quote for services, Vitatech prepares a detailed, engineered design and project management schedule, implements corrective measures, manages subcontractors, and provides a final ELF EMF survey to verify the results.

Low Frequency Magnetic Shielding

Static DC Shielding

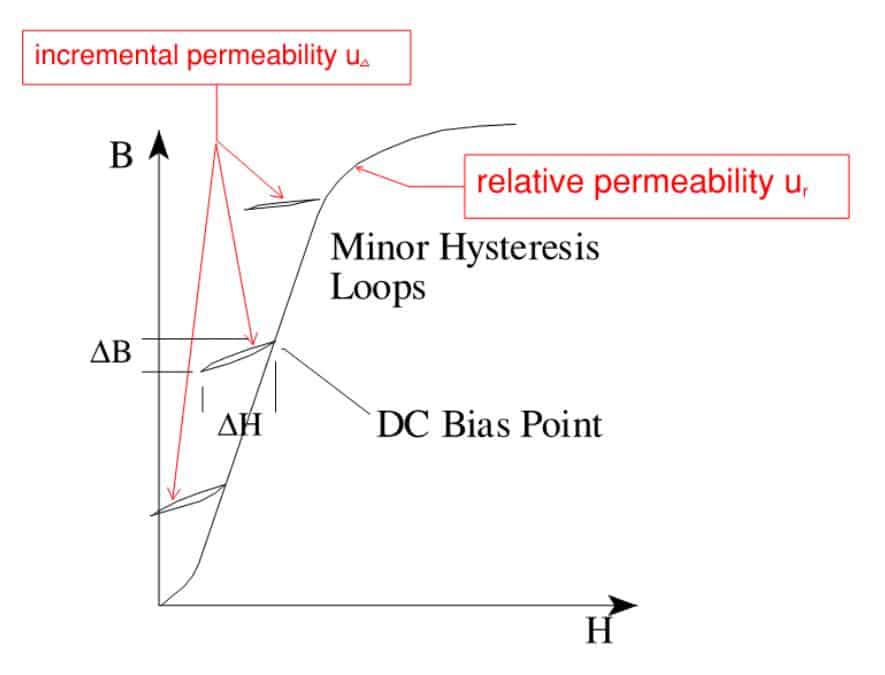

Magnetization or domain alignment within a ferromagnetic material (B induction) for a given external field is characterized by the permeability µ which is a function of the field strength H:

B = H(µ)

Relative permeability (µr) is the ratio of material permeability divided by the permeability of free space (µo). Non-ferrous materials such as aluminum have a relative permeability (µr) of less than one (paramagnetic) while hydrogen annealed mu-metal can achieve one million (ideal). To calculate the static DC shielding attenuation from geomagnetic or static DC source (i.e., NMR, MRI, etc.), the relative permeability (µr) must be ascertained from the specific material B-H non-linear curve where µr = B/H ratio between total magnetic induction (magnetic flux within the material) and magnetizing field strength H (Oersted/Gauss or A/m depending on units).

It should be noted that all ferromagnetic shielding materials including hydrogen annealed mu-metal age over time (known as magnetization impacting remanent magnetization) from geomagnetic exposure and must be periodically degaussed (expensive and time-consuming task) to return the incremental (µΔ) and relative permeability (µr) performance and attenuation.

Quasi-Static DC Shielding

Quasi-static DC magnetic fields emanate from ramping magnets, DC electrified trains, moving elevators, diesel trains, vehicles, and all ferromagnetic masses in motion. Shielding quasi-static DC fields and 50/60 Hz is based solely upon the incremental permeability µΔ properties of the ferromagnetic shielding material, and not the relative permeability (μr) which is used to calculate static DC attenuation from geomagnetic and stray MRI / NMR magnetic fields. Mill annealed mu-metal (75% nickel / 25% iron) has low (100 to 600) incremental permeability µΔ and must be hydrogen annealed (costly process) to significantly improve the quasi-static DC and 50/60 Hz shielding attenuation by a factor of 10 to 25. Hydrogen annealed mu-metal increases incremental permeability µΔ to 18,000 and defined by the bias DC field to align magnetic domains. Quasi-static DC and 50/60 Hz attenuation depends on thickness and number of hydrogen annealed mu-metal layers and nested shells.

Active Cancellation System and Shielding Demostration

AC ELF Shielding

To mitigate 50/60 Hz and higher harmonic time-varying magnetic fields, AC ELF magnetic shielding combining highly conductive plate and ferromagnetic materials provides excellent attenuation and long-term performance for the life of the shield area (sources or victim). Most AC ELF shields are constructed with highly conductive and bonded plate to achieve maximum eddy-current (lossy) shielding performance. In higher field environments where shielding must provide more than -30 dB of attenuation (field reduction of 31), it is necessary to additional layers of ferromagnetic and conductive shielding material to significantly improve the overall performance. Shielding attenuation above -60 dB of attenuation (field reduction of 1000), can be easily achieved by adding multiple layers of conductive and ferromagnetic shielding material for a very reasonable cost. AC shielding includes: six-sided shielded enclosures for maximum performance, 5-sided shielded electrical rooms, L-shaped shields for areas adjacent to electrical rooms, and enclosed busway shields for electrical risers. Vitatech also provides customized electrical panel and transformer shields.

When People Are at Risk

People are typically exposed to very high 60-Hz magnetic field levels ranging between 10-1,000 mG (milligauss) when their offices and apartments are next to, over or under transformer vaults, network protectors, secondary feeders, switchgears, distribution busways and electrical rooms. Usually employees and tenants are not aware of this potential hazard unless the magnetic field source compromises audio/video equipment, electronic instruments, magnetic storage media, VDT’s, computers, and networks. Once detected it ultimately becomes the responsibility of the building owner/manager to remedy, otherwise the employee and/or tenant may seek legal action. Unfortunately, there are only three practical solutions to mitigate magnetic field exposure produced from electrical systems within buildings: move the victims (people and equipment) away from the source, shield the source or shield the victims from the source.

RF/EMP/HEMP

RF, EMP, & HEMP Shielding.

The other invisible threat we know all about Radio Frequency Interference (RFI), is increasingly an issue for siting sensitive instruments, communications system design and operation, and human RF exposure safety.

Vitatech has shielding design expertise measuring and simulating radio-frequency (RF) threats and designing cost-effect RF shielding solutions to attenuate (reduce) elevated and high E-Field and H-Field electric field, planewave and microwave environments from 14 kHz to 26 GHz. Besides our standard and special wideband RF expertise, we simulate, design and install specialized High Altitude Electromagnetic Plus (HEMP) / EMP shielded facilities for military command centers, commercial and university research projects.

RF Shielding & RFI Mitigation

Vitatech designs and installs medium to high performance -50 dB to over -100 dB RF shielded rooms from 14 kHz to 10 GHz for human and animal research MRIs (1.5T, 3T, 7T, 9.4T, 11.7T), scientific / medical instrumentation, biomedical (EEGs, EKGs, MEGs, etc.) research, secure computer rooms, and TEMPEST / SCIF facilities. For specialized wide-band shielding projects we can integrate low frequency DC to 14 kHz static DC, quasi-static DC and time-varying 16 Hz, 25 Hz, 50 Hz & 60 Hz magnetic shielding into any type of RF (14 kHz to 10 GHz) shielded room design for maximum bandwidth, attenuation and performance.

_

EMP/HEMP Shielding

Vitatech has designed several medium to large EMP /HEMP shielded facilities, written detailed specification documents, reviewed bids & proposal, provided construction administration during on-site fabrication, and reviewed third-party HEMP / EMP final testing documentation for certification. All HEMP shielded projects were classified. EMP shielded test facility was designed to contain high-voltage EMI / RFI transient and wideband pulse emissions during controlled discharges / simulated lightning strikes.

Case Studies

Alexandria Center for Life Science

The Alexandria Center for Life Science (formerly East River Science Center) is a collaborative...

Read More625 West 57th Street

The Durst Organization 625 West 57th project is an 800,000 square-foot building of residential and...

Read More30 Rockefeller Plaza

30 Rockefeller Plaza owned by NBC Universal and Tishman Speyer, is an eight decade...

Read MoreThe Tower Companies

The Tower Companies corporate headquarters is located at 2000 Tower Oaks Boulevard. The Tower...

Read MoreGoldman Sachs

The Goldman Sachs World Headquarters is a 43-story building under construction in the Battery...

Read MoreDraeger USA

Vitatech preformed an EMF human health and exposure assessment for the Draeger Medical Systems...

Read More